Powell ORP Electrode - Brine Chlorine Operations

Anuncio

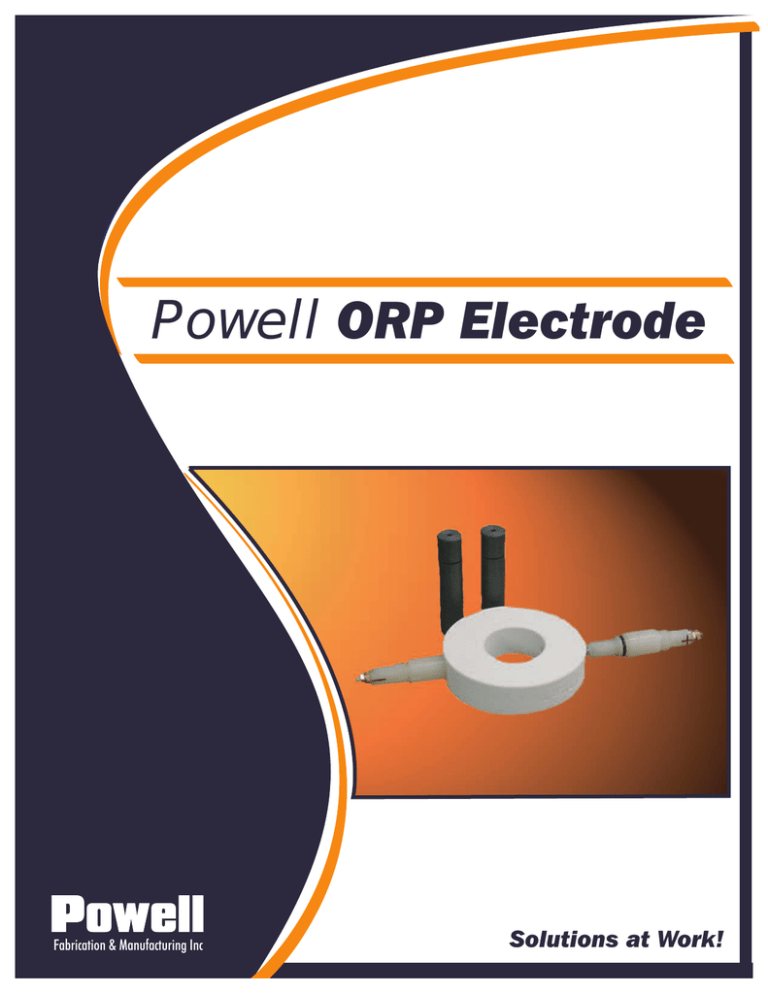

Powell ORP Electrode Powell Fabrication & Manufacturing Inc Solutions at Work! The information contained herein is, to our best knowledge, true and accurate, but all recommendations or suggestions are made without guarantee, since the conditions of use are beyond our control. Powell Fabrication & Manufacturing, Inc. disclaims any liability incurred in connection with the use of this information. Furthermore, nothing contained herein shall be construed as a recommendation to use any product in conflict with existing patents covering any material or its use. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc Powell ORP Electrode Powell ORP electrodes are currently installed in hundreds of locations worldwide, in a wide variety of process applications. This includes sodium hypochlorite batch & continuous production, room scrubbers, equipment scrubbers and packed towers, as well as in the production of ferric chloride, and monitoring the de-chlorination process of electrolyzed brine solutions. Regardless whether installed between flanges or directly into PVC piping, Powell electrodes should be installed as follows: · Always installed in redundant sets. One set designated as a primary control pair. One set designated as a secondary (back up) pair. The accuracy, repeatability and reliability of the electrodes provide excellent process control. The uncomplicated design allows for easy maintenance, provides long service life and reduces downtime. · Always be immersed in solution. Dry electrodes may cause the signal to drift, and cause an alarm. · Installed between isolation valves to allow for maintenance. Powell ORP electrodes have been proven to operate in harsh process conditions in which traditional wetted ORP electrodes have failed. Installation Overview Figure 1 – Powell ORP Cell Assembly Installs between two 150# ANSI Flanges. Shown without dust caps & wiring. ORP Cells for DIN flanges also available. Powell ORP Electrodes can be installed in the process piping in several ways. · · The Teflon® ORP ring allows the electrodes to be installed between flanges in the piping. The PVC adapters allow for installation directly into PVC piping. Figure 1: Powell ORP Cell Assembly Without Dust Caps and Wiring. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc Powell ORP Electrode Figure 2 – Powell ORP PVC Adapters Maximum installation flexibility. No changes to existing piping layout required. Not for use in lined piping systems. The output signal is in the form of millivolts, direct current (mV DC). Frequently, it is desirable to connect this millivolt signal to a transmitter for conversion to an analog current signal (4 –20 mA). A variety of transmitters are commercially available to perform this task. Some units have RTD probes to allow for temperature compensation, as well as pre-amplifiers to assist with calibration & maintenance. These are not required for Powell ORP electrodes. Generally speaking, Powell ORP electrodes can be connected to most transmitters in the same manner as a 4-20 mA calibration millivolt generator would be installed for calibration purposes. Figure 2: Powell ORP PVC Adapters Electrical Requirements Powell direct immersion ORP electrodes do not require any source of power to operate. This further simplifies installation and makes the Powell electrodes compatible with a wide variety of process control equipment. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com ORP Transmitters should have an input impedance of at least 40MW. An RTD probe connection can be “jumpered out” by installing a suitable resistor across the terminals. Please Note: Unlike KCL Wetted probes; Powell ORP Electrodes do not require temperature compensation or calibration. Powell Fabrication & Manufacturing Inc Powell ORP Electrode Typical Powell-Supplied Components Powell Stock Code: 108-03640-001 Description: TRANSMITTER 54EPH/ORP-01 A typical ORP electrode installation would be as follows: Powell 2" ORP Cell Assembly Figure 4: Powell Recommended Transmitter Powell Stock Code: 905-00062-001 Description: Consists of glass-filled Teflon® ring, one positive electrode, one negative electrode, one pair of dust caps. Designed for installation between two 2" 150# ANSI flanges. ORP Rings for DIN dimension flanges also available upon request. NEMA 4X housing with backlit display HART® programmable. Independent outputs Two programmable alarm & one fault relay Input Range: - 50 mV + 1000 mV DC Requires 115 VAC ± 10%, 50-60 Hz ± 6% Figure 3: Powell 2” ORP Cell Assembly Powell Recommended Transmitter One Transmitter is required for each ORP Cell Assembly in Service. The Transmitter Powell recommends is ar follows 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Cost includes set up, programming and wiring print by Powell. The programmable alarm set points with relay contacts allow this transmitter to provide a hardwired output to a control system, alarm circuit or process control interlock. This transmitter has been widely used by Powell for primary ORP indication on Powell continuous bleach plants. Powell Fabrication & Manufacturing Inc Chlorine Scrubber Sodium Hydroxide Control With Oxidation Reduction Potential Powell Oxidation Reduction Potential Instrumentation is the best available technology for the indication and control of sodium hydroxide concentrations for chlorine scrubbers on the market today. Powell technology has been successfully applied to chlorine scrubbing for over 40 years. Chlor-alkai production plants such as Occidental Chemical and Olin Chemical in the United States, Sasol LTD in South Africa, Orica in Australia, Carbocloro in Brazil, Occidental in Chile and many others throughout the world use proprietary Powell Oxidation Potential Electrodes for this application. When the correct electrode installation has been made using the Powell ORP electrodes, the silver/platinum electrode pair produce a millivoltage signal output according to the following formula: Where Eo is the standard oxidation potential for the reaction. Since the electrode potential is primarily a function of the hydrogen ion concentration, a sharp inflection is noted at the reaction end point similar to that obtained by pH measurements. Experience has shown that typical millivoltages in a chlorine scrubber starting with a typical 21% sodium hydroxide and reacting with chlorine will produce the following approximate mVDC signals with respect to the remaining sodium hydroxide versus the weight percent sodium hypochlorite. Data is show in Table 1. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Table 1: ORP vs Wt% NaOH Using the above to the right, the Oxidation Reduction Potential Curve with the 21% by weight sodium hydroxide starting point can be represented as a graph, as shown in Table 1. Using the proprietary Powell ORP electrodes any chlorine scrubber can be continuously or batch controlled at high sodium hydroxide levels as required by individual design of the scrubber. Powell Fabrication & Manufacturing Inc Chlorine Scrubber Sodium Hydroxide Control With Oxidation Reduction Potential If the system is automated with the application of automatic sodium hydroxide supply valves in conjunction with the Powell ORP electrodes, process upsets can be easily and quickly managed. ORP vs w t% NaOH 600 500 ORP (mV) Powell’s customers have successfully controlled by using continuous and automatic control sodium hydroxide levels at typical levels such as 12% by weight with excellent results. Many customers chose to operate the scrubbers at much lower levels of sodium hydroxide such as 1.5% using Powell ORP electrodes either by batch or continuous. 400 300 200 100 0 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 w t% NaOH Figure 4: ORP vs wt%NaOH On batch chlorine scrubbers, the Powell ORP electrodes are used to provide information and alarms to inform the operators when to change batch sodium hypochlorite tanks in the scrubbing operation. Powell has Best ORP Technology Available The Powell Oxidation Reduction Potential (ORP) Electrode utilizes platinum for the measuring electrode and silver for the reference electrode. The unit has proven itself in numerous years of service in chlorine scrubbing, sodium hypochlorite production, chlorine and bleach neutralization, and the ferric chloride industries and is suitable for use in any halogen chemical service including scrubbers, neutralization tanks, vent stacks, and batching tanks. Powell ORP Electrodes are available for 1" to 18" pipe sizes, and are known for their long service life. The Powell ORP electrodes have been designed for simple installation and maintenance. They are easy to install and repair. There are many types of installation methods to chose depending on the design of the chlorine scrubber. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com For More Information Call Powell Today Please contact Powell today and find out why companies such as Olin and Occidental can now operate their emergency chlorine scrubbers automatically and continuously with the confidence necessary in today’s environmental standards. To obtain literature, test data, engineering drawings, and/or free videotapes, Fax 989.681.5013 or e-mail your request to [email protected]. You may also call 989.681.2158 to speak with a technical representative. For immediate information, visit our web site at www.powellfab.com. The information contained herein is, to our best knowledge, true and accurate, but all recommendations or suggestions are made without guarantee, since the conditions of use are beyond our control. Powell Fabrication & Manufacturing, Inc. disclaims any liability incurred in connection with the use of this information. Furthermore, nothing contained herein shall be construed as a recommendation to use any product in conflict with existing patents covering any material or its use. [email protected]. You may also call 989.681.2158 to speak with a technical representative. For immediate information, visit our web site at www.powellfab.com. Powell Fabrication & Manufacturing Inc ORP Cell Assemblies Effective 4/01/2003 Subject to Change Without Notice Complete ORP System Standard complete unit consists of one Teflon® body ring with one silver electrode on silver rod in Kynar® holder, and one platinum electrode on brass rod in Kynar® holder, both with moisture resistant PVC caps. 1" thick 25% glass filled Teflon® units #1170 for direct insertion between 2 lined pipe companion flanges. Pipe Size 1” Stock Code Number 905-00061-001 2“ 905-00062-001 3” 905-01230-001 4” 905-01225-001 6” 905-00063-001 Components One Silver Electrode with Silver Rod, One Platinum Electrode with Brass Rod, One Teflon® body Ring for 1“ Lined pipe and Two Moisture Resistant Cap PVC. One Silver Electrode with Silver Rod, One Platinum Electrode with Brass Rod, One Teflon® body Ring for 2“ Lined pipe and Two Moisture Resistant Cap PVC. One Silver Electrode with Silver Rod, One Platinum Electrode with Brass Rod, One Teflon® body Ring for 3“ Lined pipe and Two Moisture Resistant Cap PVC. One Silver Electrode with Silver Rod, One Platinum Electrode with Brass Rod, One Teflon® body Ring for 4“ Lined pipe and Two Moisture Resistant Cap PVC. One Silver Electrode with Silver Rod, One Platinum Electrode with Brass Rod, One Teflon® body Ring for 6“ Lined pipe and Two Moisture Resistant Cap PVC. Price $ 898.00 $ 943.00 $1024.00 $1207.00 $1363.00 Larger units or special designs are available. Please contact us for details. Individual Parts Pipe Size 1” 2” 3” 4” 6” Pipe Size 1” 2” 3” 4” 6” Silver Electrodes with Silver Rod Less Cap. Stock Code Number Price 915-02355-001 $180.00 915-02351-001 $180.00 915-02369-001 $180.00 915-02367-001 $180.00 915-02364-001 $180.00 Ring only for lined pipe size. Stock Code Number Price 910-01183-001 $ 288.00 910-01185-001 $ 333.00 910-01186-001 $ 414.00 910-01189-001 $ 597.00 910-01190-001 $ 753.00 Platinum Electrrodes with Less Cap. Stock Code Number 915-02353-001 915-02357-001 915-02368-001 915-02360-001 915-02370-001 Brass Rod Price $310.00 $310.00 $310.00 $310.00 $310.00 Moisture Resistant Cap PVC Stock Code Number Price 915-02350-001 $60.00 915-02350-001 $60.00 915-02350-001 $60.00 915-02350-001 $60.00 915-02350-001 $60.00 PVC Electrode Adapters available (3/4" MIP 910-01181-001 (Each) - $ 60.00 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc ORP Cell Assemblies Effective 4/01/2003 Subject to Change Without Notice Electrode Repair Services Pipe Size 1" 2" 3" 4" 6" Silver Electrode (Negative) Stock Code Number for Repair Repair Kit Kit 916-02380-001 $105.00 916-02670-001 $105.00 916-02376-001 $105.00 916-02372-002 $105.00 916-02374-001 $105.00 Factory Re-built $125.00 $125.00 $125.00 $125.00 $125.00 Platinum Electrode (Positive) Stock Code Factory Number for Re-built Repair Kit Repair Kit 916-02381-001 $ 45.00 $55.00 916-02669-001 $ 45.00 $55.00 916-02377-001 $ 45.00 $55.00 916-02379-001 $ 45.00 $55.00 916-02899-001 $ 45.00 $55.00 Holder must be returned unbroken. Platium tips must be returned with unbroken holder. 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc Powell Fabrication & Manufacturing Inc Powell Electrode Users Includes Owners of Powell Continuous and Batch Bleach Systems A&I International, Laredo, TX Abcotek Technology, Flushing, NY Alexander Chemical Company, Multiple Locations in the United States All Pure Chemical Company, Multiple Locations in the United States Allied Chlorine, South Kearny, NIAllied Universal Corporation, Miami, FL Alpak, Edmonton, AB, Canada Altivia Corporation, Multiple Locations in the United States American Technology & Controls, Houston, TX Aqua Chlor, Fresno, CA Arden Chemical, South Kerney, NJ Basf, Geismar, LABDP International, Lester, PA BEI Hawaii, Honolulu, HI BF Goodrich Chemical Company, Multiple Locations in the United States Boise Cascade Paper Group, International Falls, MN Boise Cascade Vancouver Specilalities Mill, Vancouver, WA Brenntag Canada Inc., Multiple Locations in Canada Brenntag Mid South Inc., Multiple Locations in the United States Brewer Environmental Industries, Honolulu, HI Bristol Myers Products of Canada, Toronto, ON, Canada Burris Chemicals, Charlotte, NC Carbocloro Oxypar, Cubatao, Multiple Locations in Brazil Carrol Welding Supply Inc., Abilene, TX CDI, Multiple Locations in the United States Centrex, Inc., Houston, TX CGTX Incorporated, Red Deer, AB, Canada Chem Lab Products Incorporated, on, Canada Chem Lab Products, Inc., Multiple Locations in the United States Chemetics US, Vancouver, BC, Canada Chemetron, Holland, MI Chemical Distributors, Inc., Farmington, NM Chemply, Bunola, PA Chexport Corporation, Miami, FL Ciba Geigy Corporation, Mcintosh, AL Cincinnati Specailtites, Inc., Cincinnati, OH 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Clearon Corporation, S. Charleston, WV Cleartech Industries Inc., Multiple Locations in Canada Clorox Company, Multiple Locations Worldwide Clowhite Company, Hampton, GA Coastal Products & Chemicals, Houston, TX Colgate-Palmolive Company, Multiple Locations in Canada Colgate-Palmolive Ivory Coast, Africa Colgate-Palmolive, Reunion Island, Le Port, Cede Colgate-Palmolive, Santa Domingo, Dominican Republic Colgate-Palmolive, Valencia, Venezuela Control System Industrial, Laredo, TX CVDSA Industria Quimica Del, Monterrey, Mexico Dial Corporation, St. Louis, MO Diferco U S A Corporation, Miami, FL Dow Chemical U S A, Midland, MI DPC Enterprises, Multiple Locations in the United States Dutch Chemicals, Multiple Locations in Canada DXI, Multiple Locations in the United States E.S. Trading, Lebanon Eaglebrook, Varennis, GB, Canada Ecolab, Garland, TX Economics Lab, St. Paul, MN Electrolytic Technologies Corporation, North Miami Beach, FL EMD Chemicals Inc., Savannah, GA ERCO, Saskatoon, SK, Canada Escort Forwarding, Inc., Inwood, NY Flexsys America LP, Nitro, WV FMC Corporation, Nitro, WV Fraser Paper, Park Falls, WI G & O Supply Company, Laredo, TX G A C Chemical, Multiple Locations in the United States GATX Rail, Colton, CA Geon Company, Cleveland, OH George Mann & Company Inc., Providence, RI Georgia Pacific Corporation, Kalamazoo, MI GPS Industries Division, City of Industry, CA Great Lakes Chemical Corporation, Nitro, WV Powell Fabrication & Manufacturing Inc Powell Fabrication & Manufacturing Inc Powell Electrode Users Includes Owners of Powell Continuous and Batch Bleach Systems Great Lakes Process Controls, Inc., Farmington Hills, MI Great Western Chemical, Salt Lake City, UT Groupe Lavo Inc., Montreal, PG, Canada H. Krevit & Company, Inc., New Haven, CT Harcros Chemical, Multiple Locations in the United States Hasa Inc., Multiple Locations in the United States Hawkins Inc., Multiple Locations in the United States HCI, Multiple Locations in Canada Hector Vaca Esparza, Monterrey, Mexico Herbert Verkamp Calvert, Cincinnati, OH High-Po-Chlor, Romulus, MI Hill Bros. Chemical, Phoenix, AZ Hydrite Chemical Company, Oshkosh, WI I C I Americas Inc., Multiple Locations in the United States I C I Canada Incorporated, Cornwall, ON, Canada I C I, Sydney, Australia Impex International Associates Inc., Dodgeville, WI Inchem, Manilla Industria Quimica Del ISTM, Canada Industria Quimica Del Istmo Sa De CV, Monterrey, N.l. Industria Quimica Del Istmo, Multiple Locations in Mexico Industrial Innovations, Stockton, CA Industrial Sales & Service Company, Henderson, NY Inquista Chemical, Monterrey, Nuevo Leon, Mexico Intercore, Jorden International Chemical, Binondo, Manila, Philippines ISA, Feasterville, PA James Austin Company, Multiple Locations in the United States JCI Jones Chemical Inc., Multiple Locations in the United States KA Steel Chemicals, Multiple Locations in the United States KEM Iron, Multiple Locations in the United States Kemira Pigments, Inc. Savannah, GA Kemwater North America Company, Multiple Locations in the United States 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Kerr Mcgee Pigments (Savannah), Inc., Livonia, MI KIK Inc., Multiple Locations in the United States KIK Toronto Inc., Concord, ON, Canada Kvaerner Chemetics, Riegelwood, NC Kvaerner Chemetics, Vancouver, BC, Canada L’ Environment Eaglebrook, Varennes, PG, Canada Labbco of Louisiana, Slidell, LA Mabuhay Vinyl Corporation, Philippines Manley Regan Chemicals, Middletown, PA Marsulex, Fort Saskatchewan, AL, Canada Miami Products, Dayton, OH Monsanto Chemical Company, Multiple Locations in the United States Nortim Inc., Winston Salem, NC Noveon, Inc., Multiple Locations in the United States Noveon, the Netherlands Occidental Chemical Corporation, Multiple Locations in the United States Odyssey Manufacturing, Tampa, FL Olin Chemical, Multiple Locations in the United States Olympic Chemical, Fontana, CA Online Packaging, Plover, WI Oregon metallurgical Corporation, Albany, NY Oremet, Albany, OR Orica Australia Pty, LTD., Melborne, Australia Oxy Vinyls LP, Multiple Locations in the United States P P G Canada, Inc., Beauharnois, PG, Canada Pares & Alvarez, Concepcion, Chile PB & S Chemical Company, Inc., Multiple Locations in the United States PCI Canada, Montreal, QB, Canada Penford Products Company, Cedar Rapids, IA Pennwalt S.A. de C.V., Ecatepec, Edo. Mexico Pennwalt S.A. de C.V., Brownsville, TX Phibro-Tech, Inc., Joliet, IL Pioneer Americas, Inc., Multiple Locations in the United States Pioneer Cornwall Works, Multiple Locations in the Canada PMC Specialties LLC. , Cincinnati, OH Polifin Limited, Sasolburg, Republic of South Africa Powell Fabrication & Manufacturing Inc Powell Fabrication & Manufacturing Inc Powell Electrode Users Includes Owners of Powell Continuous and Batch Bleach Systems PPG Canada Incorporated, Beauharnois, QB, Canada PPG Industries, Multiple Locations in the United States Prairie Chemical, Multiple Locations in the Canada Prillaman Chemical, Suffolk, VA Proctor & Gamble Paper Company, Green Bay, WI Prodesal, Cali, Colombia Quimica Pima, Sonora, Mexico Quimicos, Holanda, Costa Rica Quinta Raddison Limited, Inwood, NY Quinta Raddison, LTD., Colchester, England Rawabi Marketing International, Olaya-Riydh, Saudi Arabia Rayonier, Jesup, GARES, Inc., Middletown, DE Rowell Chemical, Multiple Locations in the United States Sachem, Inc., Multiple Locations in the United States Sasol Technology pty., ltd., sasolburg, South Africa Sentry Industries, Miami, FL Sewell Products, Auburndale, FL Sierra Chemical, Multiple Locations in the United States SO White Chemical Company, Plover, WI Southwestern Chemical, Cleburne, TX Staley A E Manufacturing Company, Decatur, IL Stanchem, Multiple Locations in Canada Star Trade International LLC., Marietta, GA Sterling Pulp Chemicals, SK, Canada Summit Industries, Mt. Pleasant, TN Surpass Chemical, Albany, NY Taiwan Chlorine Industries, Kaoksiung, Taiwan TC Products, Tacoma, WAT-Chem Products, Santa Fe Springs, CA Technochem, Inc., Plantation, FL Thatcher Chemical Company, Multiple Locations in the United States Trinity Manufacturing, Hamlet, NC Ulrich Chemical, Terre Haute, IN 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Ulysses, NigeriaUnivar USA Inc., Multiple Locations in the United States Vertex Chemical, Corp., Multiple Locations in the United States Vicksburg Chemical Company, Vicksburg, MS Wausau Papers, Brokaw, WI Wonder Chemical Corporation, Fairless Hills, PA Powell Fabrication & Manufacturing Inc Owners of Powell Continuous Bleach Plant System 1967 Wonder Chemical Corporation, Fairless Hills, Pennsylvania Tops Chemical (Georgia-Pacific) Richmond, California 1968 Georgia Pacific, City of Commerce, California Hasa Chemicals Inc., Saugus, California 1969 Jones Chemicals, Inc., Warwick, New York Sun Chemicals, Inc (FMC Corp. Detroit, Michigan) 1970 Kare Kemicals, Inc., Opa-Locka, Florida Jones Chemicals, Inc., Barberton, Ohio 1971 Dow Chemical U.S.A., Midland, Michigan Hasa Chemical, Eloy, Arizona Jones Chemicals, Inc., Beech Grove, Indiana 1972 Canadian Forest Products, Port Mellon, British Columbia, Canada Canadian Miraclean (Prairie Chem) 1973 Georgia-Pacific Corporation, Kalamazoo, Michigan Hydrite Chemical, Converted To Alternate Chemical Production 1975 Jones Chemicals, Inc., Fort Lauderdale, Florida 1976 Proctor & Gamble, Green Bay, Wisconsin Bristol Myers (Colgate-Palmolive), Toronto, Ontario, Canada 1977 Jones Chemicals, Inc., Houston, Texas, Jones Chemical, Inc., Merrimac, New Hampshire Jones Chemical, Inc., Milpitas, California Jones Chemical, Inc. Charlotte, North Carolina 1980 Ciba-Geigy Corporation, McIntosh, Alabama 1981 Hasa Chemicals Inc., Eloy, Arizona High-Po-Chlor, Romulus, Michigan Sun Wholesale Supply (HCI Clearwater Chemical), Clearwater Florida 1982 Aqua Chlor, Purchased By All Pure Chemical, Tracy, California Economics Labs (Ecolab), Joliet, Illinois 1983 Alexander Chemicals, Kingsbury, Indiana Purex Corporation (The Dial Corporation) Broadview, Illinois 1984 Patterson Laboratories, Detroit Michigan HVC Chemical, Cincinnati, Ohio U.S. Chlorine, Inc. (Sentry Industries), Miami, Florida 1985 GPS Industries Division, City of Industry, California KA Steel Chemical, Inc., Lemont, Illinois Hydrite Chemical Company, Oshkosh, Wisconsin Union Sanitary District (Jones Chemical) Torrence, California Jones Chemical, Torrance, California T-Chem, Santa Fe Springs, California 1986 Boise Cascade Paper Group, International Falls, Minnesota AE Staley Mfg. Co., Decatur, Illinois (sold to Jones Chemical) The Dial Corporation, (Purex) Southgate, California Monsanto Chemical (Flexsys America, LP), Nitro, West Virginia All Pure Chemical, Santa Fe Springs, California H. Krevit & Co., New Haven, Connecticut Proctor & Gamble, Grand Prairie, Alberta, Canada Flambeau Paper Corporation, Park Falls, Wisconsin 1978 Bristol Myers (Colgate Palmolive) Moncton, New Brunswick 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc Owners of Powell Continuous Bleach Plant System 1987 George Mann, Providence, Rhode Island Hawkins Chemical, Minneapolis, Minnesota DPC Industries, Houston, Texas Dial Corporation, Auburndale, Florida Dial Rebuild, St. Louis, Missouri 1988 Clorox, Forest Park, Georgia Prairie Industrial Chemical (Prairie Chem Inc.) Calgary, Canada Stanchem, Division Of Cil, Winnipeg, Manitoba, Canada Ulrich Chemical Inc., Terre Haute, Indiana DPC Industries, Rosemount, Minnesota 1989 Wausau Paper Mills Company, Brokaw, Wisconsin Manley-Regan Chemicals, Middletown, Pennsylvania Boise Cascade Paper Group, Vancouver, Washington Cil Inc. (Pioneer Americas) Cornwall, Ontario, Canada 1991 Penford Products, Cedar Rapids, Iowa Chemply, Pittsburgh, Pennsylvania DPC Industries, Albuquerque, New Mexico DPC Industries, Cleburne, Texas 1992 Prillaman, Suffolk, Virginia Rowell, Hindsdale, Illinois Bleach Masters, Inc., Charlotte, North Carolina Mabuhay Vinyl Corporation, Makati, Metro Manila, Philippines 1993 Litehouse Industries Limited, Guelph, Ontario, Canada Groupe Lavo, Inc., (Dutch Chemicals, Inc.), Weston, Canada 1994 KA Steel Chemical, Inc., Lemont, Illinois Jones Chemical, Inc., Milpitas, California Sierra Chemical, Sparks, Nevada 1995 Hasa Inc., Pittsburgh, California Chemical Formulators, Tampa, Florida 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com 1996 Coastal Products & Chemicals, Houston, Texas Occidental Chemical Corporation, Talcahuano, Chile Thatcher Chemical Company, Salt Lake City, Utah Van Waters & Rogers, Inc., Spartansburg, South Carolina Sierra Chemical, Sparks, Nevada Colgate-Palmolive, Edmonton, Alberta, Canada 1997 HCI Chemtech, Chesterfield, Missouri Taiwan Chlorine Industries, Koahsiung, Taiwan 1998 DPC Industries, Reserve, Louisiana Inchem, Philippines Thatcher, Salt Lake City, Utah DPC Industries, Houston, Texas 1999 Clorox, Chicago, Illinois Clorox, Aberdeen, Maryland (2) Odyssey Manufacturing, Tampa, Florida GAC Chemical, Indianapolis, Indiana 2000 KIK International, Concord, Ontario, Canada Carbocloro Oxypar, Cubatao, Brazil Occidental Chemical Corp, Niagara Falls, New York KIK International, Salem, Virginia 2001 Miami Products & Chemical, Dayton, Ohio Hills Brothers Chemical, Phoenix Arizona Rawabi Marketing International, Olaya-riyadh, Saudi Arabia Olin Corporation, Charleston, Tennessee Harcross/GAC Chemical Joint Venture, Searsport, Maine James Austin Company, Mars, Pennsylvania 2002 Olin Corporation Augusta, Georgia Prodesal, SA Cali, Columbia KIK Corporation, Houston, Texas 2003 Borden Remington Fall River, MA Chem Lab Products, Ontario, California Univar USA Inc., Suffolk, Virginia Hasa Chemical, Sagus, California Jones Chemical, Warwick, New York Powell Fabrication & Manufacturing Inc Guide to Powell Products and Services Sodium Hypochlorite Process Systems Process Systems: continuous, batch, skid-mounted batch Neutralization Systems: batch, continuous Sodium/Ammonium Bisulfite Systems: batch, continuous Chlor-Alkali Plants/Complete Process Systems Complete process systems interfacing all components, including chlorine tank car unloading systems with chlorine detectors, Powell chlorine scrubber, Powell chlorine tank car padding system, Powell continuous bleach plant, Powell bleach filter system, Powell bleach dilution system and all automatic process controls including tank level control systems. Powell bleach plant and scrubber can also be integrated into the DCS system of a membrane cell plant. Bleach Filter Systems Filter Systems: 100, 200, or 300 square feet filter-aided bleach filter system, plate and frame filter press Chlorine Containment & Handling Equipment Emergency Scrubber: for 150-lb cylinders, 1-ton containers, and multi-ton bulk storage for a variety of pressurized gases Equipment Scrubbers: stationary, portable Padding Systems: air, nitrogen Unloading Systems: tank car, tank truck Control Panels and Instrumentation System Upgrade: for relay logic and older instrumentation and controls ORP Electrodes: ORP/pH control, flow, ratio, and level control Continuous Dilution Systems: bleach, caustic, HCl, methanol, sulfuric acid Gas Detectors: chlorine, sulfur dioxide, variety of other gases Valve Closure Systems MaxPro™ V Valve Closure System: for 150-lb Cylinders MaxPro™ RA Valve Closure System: for 1-Ton Containers UniPro™ Valve Closure System: for plug-type and ball-type angle valves on railcars, bulk containers, tank trucks AutoPro™ Valve Closure System: for pressurized gas containers Chlorine Line Equipment Transfer Hose: Monel® hose, Teflon® complies with The Chlorine Institute, Inc. Pamphlet 6 recommendations Handlebar Union: Viton® O-ring seal, 4000# forged steel construction Expansion Tank: Designed in accordance with The Chlorine Institute, Inc. recommendations, Pamphlet 6, Section 5.5, Drawing 136 (13.1.22) Type B. Pressure Gauges, Switches, Transmitters: Ashcroft gauge; Static O-ring (SOR) pressure switch Grease, Oil: Silicone grease, halocarbon grease and oil Valves: Durco, Jamesbury, Masoneilan, Asahi, Automax Pumps: Durco, Innomag 740 East Monroe Rd St Louis MI 48880 Phone 989.681.2158 Fax 989.681.5013 email [email protected] website www.powellfab.com Powell Fabrication & Manufacturing Inc