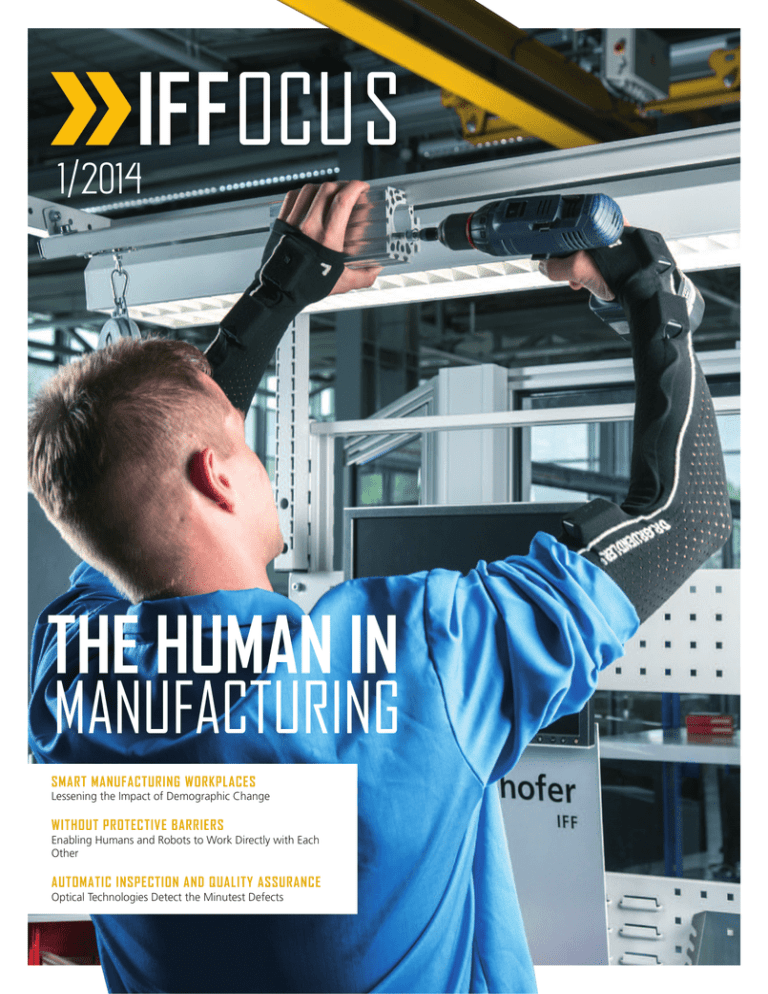

IFFOCUS: The Human in Manufacturing - Fraunhofer

Anuncio