EPT-4 0 0 S e rie s Pu m p in g Tra p

Anuncio

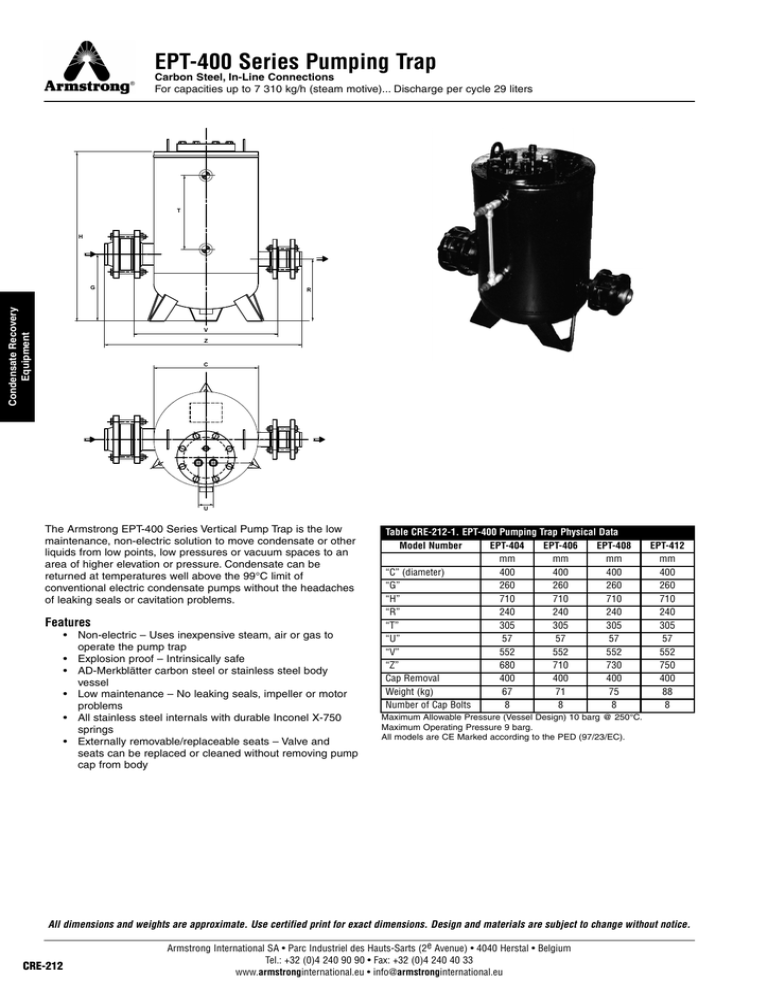

EPT-4 0 0 S e rie s Pu m p in g Tra p Carbon Steel, In-L ine Connec tions Fo r c a p a c ities u p to 7 3 1 0 kg /h (s tea m m o tive)... D is c h a rg e p er c y c le 2 9 liters T H Cond ens ate R ec ov ery E q u ip m ent G R V Z C U Th e A rm s tro n g E P T-4 0 0 S eries Vertic a l P u m p Tra p is th e lo w m a in ten a n c e, n o n -elec tric s o lu tio n to m o ve c o n d en s a te o r o th er liq u id s fro m lo w p o in ts , lo w p res s u res o r va c u u m s p a c es to a n a rea o f h ig h er eleva tio n o r p res s u re. C o n d en s a te c a n b e retu rn ed a t tem p era tu res well a b o ve th e 9 9 ° C lim it o f c o n ven tio n a l elec tric c o n d en s a te p u m p s with o u t th e h ea d a c h es o f lea kin g s ea ls o r c a vita tio n p ro b lem s . F e a tu re s • N o n -elec tric – U s es in ex p en s ive s tea m , a ir o r g a s to o p era te th e p u m p tra p • E x p lo s io n p ro o f – In trin s ic a lly s a fe • A D -M erkb lä tter c a rb o n s teel o r s ta in les s s teel b o d y ves s el • L o w m a in ten a n c e – N o lea kin g s ea ls , im p eller o r m o to r p ro b lem s • A ll s ta in les s s teel in tern a ls with d u ra b le In c o n el X -7 5 0 s p rin g s • E x tern a lly rem o va b le/rep la c ea b le s ea ts – Va lve a n d s ea ts c a n b e rep la c ed o r c lea n ed with o u t rem o vin g p u m p c a p fro m b o d y Ta b le C R E-2 1 2 -1 . EPT-4 0 0 Pu m p in g Tra p Ph y s ic a l D a ta M odelN um ber EPT-4 0 4 EPT-4 0 6 EPT-4 0 8 mm mm mm “ C ” (d ia meter) 400 400 400 “G ” 260 260 260 “H ” 710 710 710 “R ” 240 240 240 “ T” 305 305 305 “U ” 57 57 57 “V ” 552 552 552 “Z ” 6 80 710 730 C a p R emo v a l 400 400 400 Weig h t (k g ) 67 71 75 N u mb er o f C a p B o lts 8 8 8 EPT-4 1 2 mm 400 260 710 240 305 57 552 750 400 88 8 M a x im u m A llo wa b le P res s u re (Ves s el D es ig n ) 1 0 b a rg @ 2 5 0 ° C . M a x im u m O p era tin g P res s u re 9 b a rg . A ll m o d els a re C E M a rked a c c o rd in g to th e P E D (9 7 /2 3 /E C ). All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. CRE-2 1 2 Arms tro n g In tern a tio n a l S A • P a rc In d u s triel d es H a u ts -S a rts (2 e Av en u e) • 4 0 4 0 H ers ta l • B elg iu m Tel.: + 3 2 (0 )4 2 4 0 9 0 9 0 • F a x : + 3 2 (0 )4 2 4 0 4 0 3 3 w w w .a rm s tro n g in tern a tio n a l.eu • in fo @ a rm s tro n g in tern a tio n a l.eu EPT-4 00 S e rie s Pu m p in g Tra p Carbon Steel, In-L ine Connec tions Fo r c a p a c itie s u p to 7 3 1 0 kg /h (s te a m m o tive )... D is c h a rg e p e r c yc le 2 9 lite rs Ta b le C R E-2 1 3 -1 . EPT-4 00 Pu m p in g Tra p C o n n e c tio n S iz e s EPT-4 04 EPT-4 06 EPT-4 08 Inlet D N 25 D N 40 D N 50 Inlet C h ec k Va lv e D N 25 D N 40 D N 50 O u tlet D N 25 D N 40 D N 50 O u tlet C h ec k Va lv e D N 25 D N 40 D N 50 M o tiv e Va lv e 1 /2 " B S P T Vent Va lv e 1"BSPT B o d y D ra in 1 /2 " N P T G a u g e G la s s 1 /2 " B S P T C y c le C o u nter 1 /2 " B S P T EPT-4 1 2 D N 80 D N 80 D N 50 D N 50 Ta b le C R E-2 1 3 -2 . EPT-4 00 Pu m p in g Tra p M a te ria ls F a b ric a ted S teel P 2 6 5 G H /P 2 7 5 H B o d y a nd C a p AD -M erk b lä tter C a p G a s k et C o m p res s ed N o n-As b es to s B o lts SA- 193 gr B7 Inlet Va lv e As s em b ly S ta inles s S teel Vent Va lv e As s em b ly S ta inles s S teel Va lv e As s em b ly W a s h ers Z inc -P la ted S teel M ec h a nis m As s em b ly C a s t S ta inles s S teel P lu g S teel S p ring s Inc o nel X -7 5 0 EPT-4 08 D N 50x D N 50 S te a m A ir k g /h k g /h 2 245 2 420 3 295 3 495 3 540 3 680 3 590 3 695 3 640 O n req u es t 3 695 O n req u es t 2 695 3 090 3 145 3 395 3 245 3 445 3 345 O n req u es t 3 395 O n req u es t 2 095 2 470 2 895 3 195 2 990 3 245 3 050 O n req u es t 3 195 O n req u es t 2 170 2 675 2 545 3 000 2 845 3 185 2 990 O n req u es t 3 095 O n req u es t 1 900 2 520 2 045 2 580 2 245 O n req u es t 2 395 O n req u es t EPT-4 1 2 D N 80x D N 50 S te a m A ir k g /h k g /h 3 740 4 045 5 490 5 815 5 840 6 060 5 990 6 160 6 040 O n req u es t 6 090 O n req u es t 3 590 4 130 5 190 5 615 5 390 5 715 5 490 O n req u es t 5 590 O n req u es t 3 445 4 070 4 840 5 410 4 990 5 440 5 090 O n req u es t 5 190 O n req u es t 2 895 3 555 3 445 4 070 3 790 4 240 4 045 O n req u es t 4 240 O n req u es t 2 500 3 315 2 695 3 445 2 995 O n req u es t 3 195 O n req u es t Cond ens ate R ec ov ery E q u ip m ent Ta b le C R E-2 1 3 -3 . EPT-4 00 Pu m p in g Tra p C a p a c itie s (3 00 m m F illin g H e a d ) EPT-4 04 EPT-4 06 M o tiv e To ta l L ift o r D N 25 x D N 25 D N 40x D N 40 Pre s s u re B a c k Pre s s u re S te a m A ir S te a m A ir bar bar k g /h k g /h k g /h k g /h 1 ,0 945 1 120 1 545 1 670 1 ,7 1 250 1 320 2 290 2 430 3 ,5 1 545 1 610 2 440 2 454 0 ,3 5 5 ,0 1 695 1 750 2 595 2 645 7 ,0 1 750 O n req u es t 2 695 O n req u es t 8 ,5 1 800 O n req u es t 2 745 O n req u es t 1 ,7 1 100 1 260 1 750 2 010 3 ,5 1 300 1 400 2 045 2 210 5 ,0 1 ,0 1 400 1 475 2 195 2 370 7 ,0 1 545 O n req u es t 2 400 O n req u es t 8 ,5 1 595 O n req u es t 2 440 O n req u es t 2 ,5 1 000 1 170 1 445 1 710 3 ,5 1 200 1 335 2 000 2 245 5 ,0 1 ,5 1 300 1 400 2 145 2 270 7 ,0 1 400 O n req u es t 2 345 O n req u es t 8 ,5 1 450 O n req u es t 2 980 O n req u es t 3 ,5 945 1 170 1 595 2 025 4 ,0 1 100 1 300 1 800 2 125 5 ,0 3 ,0 1 200 1 335 2 000 2 235 7 ,0 1 250 O n req u es t 2 095 O n req u es t 8 ,5 1 350 O n req u es t 2 245 O n req u es t 4 ,5 900 1 200 1 595 2 145 5 ,0 1 000 1 220 1 750 2 320 4 ,0 7 ,0 1 360 O n req u es t 1 850 O n req u es t 8 ,5 1 200 O n req u es t 1 900 O n req u es t N otes : A b o ve c a p a c itie s a re th e re s u lts o f ac tu al s te a m te s tin g u s in g a m in im u m 9 3 ° C c o n d e n s a te . P u b lis h e d c a p a c itie s a re b a s e d o n th e u s e o f e x te rn a l c h e c k va lve s s u p p lie d b y A rm s tro n g . Fill h e a d m e a s u re d fro m d ra in p o in t to to p o f p u m p c a p . D is c h a rg e p e r c yc le : 2 9 lite rs . Ta b le C R E-2 1 3 -4 . EPT-4 00 C a p a c ity C o n v e rs io n F a c to rs fo r O th e r F ill H e a d s F illin g H e a d (m m ) M odel 0 150 3 00 6 00 9 00 E P T-4 0 4 0 ,7 0 0 ,8 5 1 ,0 0 1 ,3 0 1 ,4 0 E P T-4 0 6 0 ,7 0 0 ,8 5 1 ,0 0 1 ,2 0 1 ,3 5 E P T-4 0 8 0 ,7 0 0 ,7 0 1 ,0 0 1 ,2 0 1 ,3 5 E P T-4 1 2 0 ,7 0 0 ,8 5 1 ,0 0 1 ,0 8 1 ,2 0 N ote: Fillin g h e a d is m e a s u re d fro m d ra in o f re c e ive r to to p o f p u m p 's c a p . O p tio n s • S ta in le s s 3 1 6 L B o d y a n d C a p • G a u g e G la s s A s s e m b ly w ith G u a rd s (B ra s s o r C a d iu m P la te d C a rb o n S te e l) • D ig ita l C yc le C o u n te r (O p e n o r C lo s e d S ys te m s ; w ith o r w ith o u t A u x ilia ry c o n ta c ts ) • In s u la tio n J a c ke t T h is p u m p m ig h t b e s u ita b le fo r s p e c ia l a p p lic a tio n s . P le a s e c o n s u lt fa c to ry All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. Arm s tro ng Interna tio na l S A • P a rc Ind u s triel d es H a u ts -S a rts (2 e Av enu e) • 4 0 4 0 H ers ta l • B elg iu m Tel.: + 3 2 (0 )4 2 4 0 9 0 9 0 • F a x : + 3 2 (0 )4 2 4 0 4 0 3 3 w w w .a rm s tro n g interna tio na l.eu • info @ a rm s tro n g interna tio na l.eu CRE-2 1 3